Skip to content

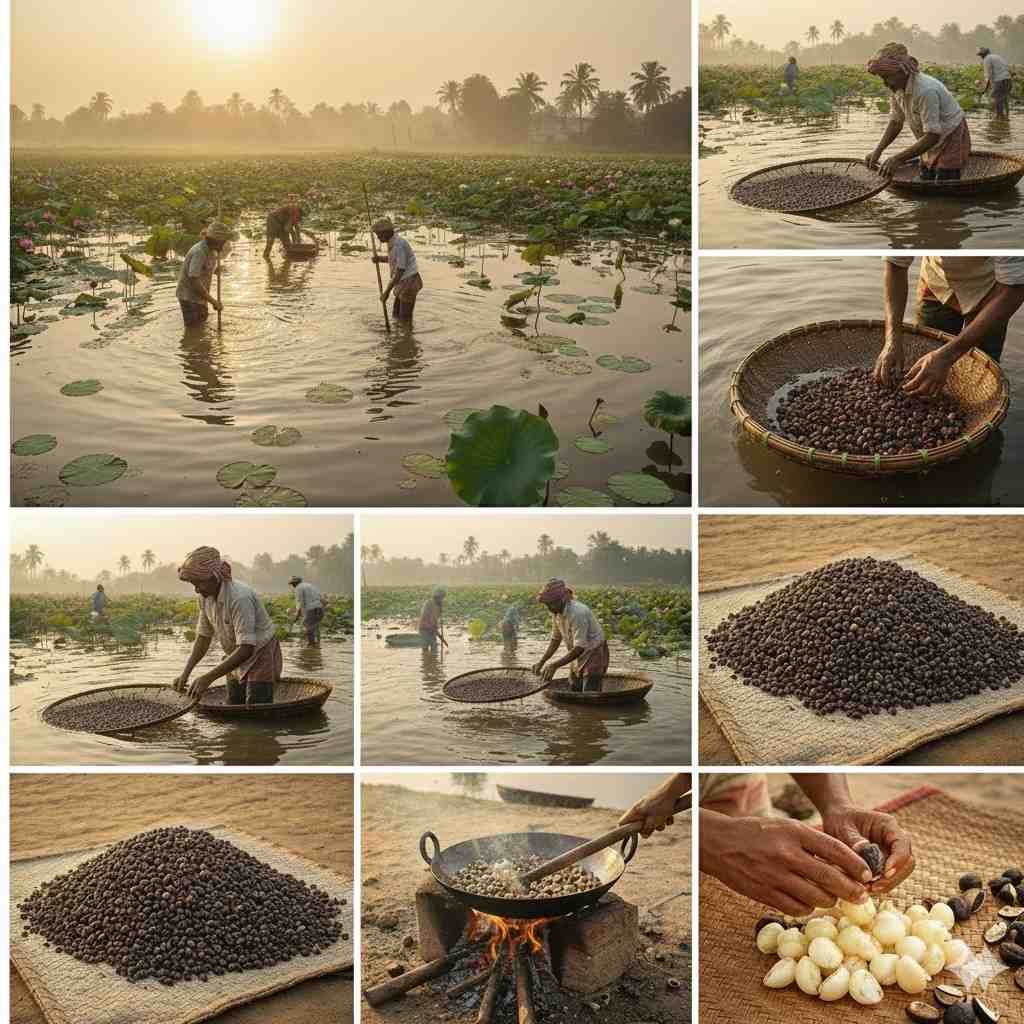

- Harvesting: Farmers collect spiky, round fruits from Euryale ferox (fox nut/water lily) plants in shallow ponds, extracting the hard, black seeds inside.

- Drying & Cleaning: Seeds are sun-dried to reduce moisture and then rolled to rub off their outer layer, with some black seeds being separated.

- Grading: The dried seeds are passed through sieves to sort them by size.

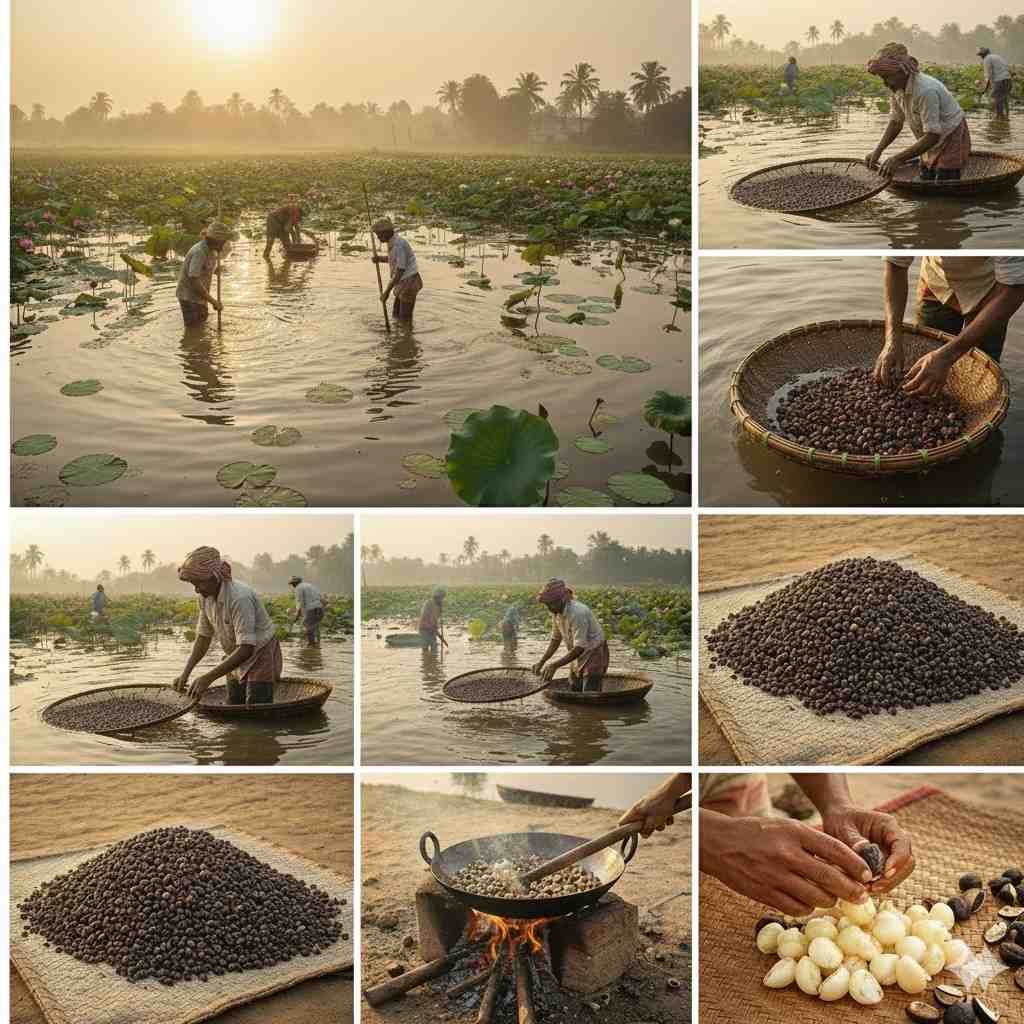

- Roasting (Stage 1): Seeds are gently heated in clay pans for about 5-6 minutes, which makes their insides starchy and prepares them for popping.

- Resting: The semi-processed seeds are spread out and left for a day or two.

- Popping (Stage 2): The seeds are roasted again, often in sequence through multiple woks, at high temperatures (250-300°C) until they pop open.

- Pounding & Cleaning: The popped, steamed Makhana are pounded on flat stones, causing the black shells to fall off, revealing the white, puffy kernels.

- Finishing: The puffs are carefully cleaned and packed for sale, sometimes with added oils and spices for flavor.